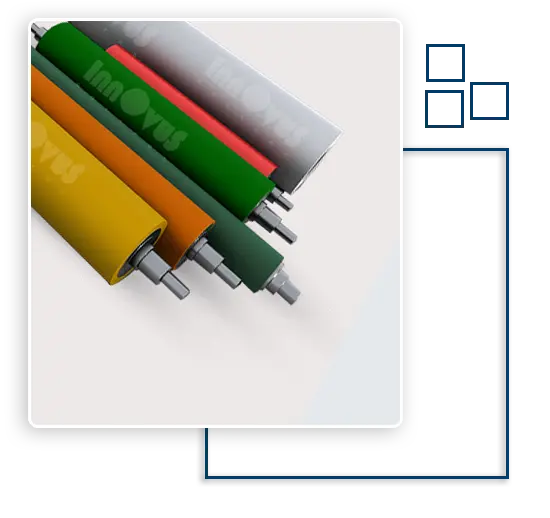

Rubber Rollers in India

Rubber Roller Manufacturer

Innovus Rollers is your go-to source for precision-engineered Rubber Rollers with features that are dimensionally accurate, dynamically balanced, and that can withstand high loads. As a top-ranked Rubber Roller Manufacturer in Ahmedabad, we deploy Nitrile (NBR), EPDM, Hypalon, Neoprene, and Silicone Rubber compounds - each serving a different kind of operational environment. Our rollers undergo dynamic balancing to concentricity at the micron level, thereby ensuring smooth, non-vibrating operation even under high peripheral speeds and elevated-temperature conditions.

Rubber Roller Exporters

Each Industrial Rubber Roller of Innovus is subjected to a controlled vulcanization and precision grinding operation to attain uniform hardness (25–100 Shore A) and surface quality. The cores of the rollers are made from the shafts of either seamless mild steel or stainless steel and are rad-hardening and corrosion-resistant treated. Furthermore, the rollers possess high tensile strength, controllable elasticity, and very good compression set characteristics - thus they are perfect for printing, textile, lamination, and coating lines that run continuously.

Custom-Built Solutions for Complex Manufacturing Needs

Innovus Rollers provides the Rubber Rollers configured for the customer's needs, precisely matching the application requirements, including surface roughness (Ra 0.2–1.6 µm), rubber compound, and bearing load. To extend the life of the roller and improve its adhesion under conditions of high-torque, solvent-rich, or abrasive environments, we provide the application of special coatings and bonding agents. Being one of the leading Rubber Roller Manufacturers in India, we offer precision-engineered solutions that enhance web stability, print accuracy, and the total efficiency of the production process.

Applications of Rubber Rollers

- Printing and packaging machinery

- Textile calendaring and dyeing machines

- Lamination and coating plants

- Paper and film converting lines

- Plastic extrusion and slitting units

- Steel, aluminum, and foil processing systems

- Web guiding, tensioning, and spreading mechanisms

Key Features of Our Rubber Rollers

- Excellent abrasion resistance

- High dynamic stability

- Superior bonding strength

- Precision-ground surface finish

- Uniform hardness distribution

- Resistance to heat and solvents

- Long service life and low maintenance

Partner with Innovus Rollers – Precision That Drives Performance

From concept to completion, we roll with you. As an industry leader in Rubber Roller Manufacturing in Ahmedabad, Innovus Rollers provides engineered solutions that deliver dimensional stability, energy efficiency, and flawless surface contact.

Contact Innovus Rollers today for customized rubber roller solutions designed to meet the highest industrial standards of precision and reliability.